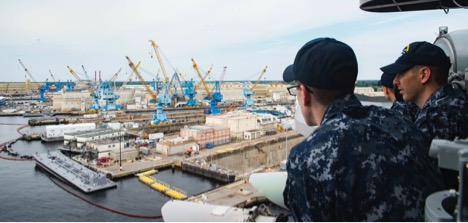

The US Navy Using Digital Tools to Reshape Approach to Operating Shipyards

In a story published on April 5, 2019 by USNI News, Megan Eckstein focused on the new US Navy shipyard modernization approach.

The Navy is creating “digital twins” of its four public shipyards so engineers can conduct modeling and simulation and identify ideal new configurations for the yards to boost productivity.

As part of its 20-year, $21-billion effort to modernize and optimize the four yards, the Navy is in the early stages of this simulation work, meant to show potential new layouts of the yards’ welding shops, pump shops, material storage, office spaces and more could contribute to better workflow and reduced man hours.

The Shipyard Infrastructure Optimization Plan (SIOP) effort will also include repairing and enhancing dry docks and replacing aging capital equipment, but the Navy hopes to hash out the layout issues early on to avoid installing large capital equipment and then having to move it a few years later.

“The Shipyard Infrastructure Optimization Plan articulated a vision that shipyard infrastructure has three interdependent components: the dry docks, the facilities and the capital equipment; and that these configurations are fundamentally linked to the shipyards’ ability to execute the mission they are tasked to do,” Steven Lagana, program manager for the SIOP effort at Naval Sea Systems Command (NAVSEA), said in a Navy news release this week.

“We are utilizing modeling and simulation as a tool to integrate these components to better inform the desired infrastructure layout. Through this, the Navy will be in a better position to make meaningful, long-lasting investments that not only address the condition of the facilities and equipment but also change the way the work is conducted. Once we’re finished, the Navy will recover more than 300,000 work days per year, every year.”

For the rest of the article, see the following:

Navy Simulating Efficient Shipyard Layouts as Part of 20-Year Modernization, Optimization Effort