Australia’s Submarine Transition: Taking a Comprehensive View

In 2009, Kevin Rudd’s government decided to increase Australia’s submarine capability. It wrote in its defence white paper: ‘The Government will increase the size of the submarine force from six to 12 boats. The doubling in size of the submarine fleet recognises that Australia will face a more challenging maritime environment in the decades ahead.’ The goal was to start getting new boats by around 2025.

While the precise numbers, the preferred design and the timelines have changed over the past 13 years, no Australian government has walked back from the basic assessment that we need more submarine capability. But even though subsequent strategic assessments have emphasised that our ‘more challenging maritime environment’ is becoming more dangerous even more rapidly than we had expected, we’re still no closer to having more submarine capability.

When the previous government announced in September 2021 that Australia would acquire nuclear-powered submarines (SSNs), it said it expected the first ones to be delivered in the late 2030s. Richard Marles, the minister for defence in the new government, has said the mid-2040s is more likely. Throughout that long period, Australia’s submarine capability will continue to comprise two deployable Collins-class submarines—the same capability we had back in 2009 when the long, meandering journey first started. It’s like saying on the eve of the First World War that you need more military power and not getting anything until after the Second.

We need to investigate every possible option to get more submarine capability sooner. Which brings us to the recent comments of Peter Dutton, former defence minister and current leader of the opposition. Despite being a member of the government that said we could expect the first SSNs in the late 2030s, Dutton now says he had a ‘plan’ to acquire two US Virginia-class SSNs off an existing American production line by the end of this decade. A further eight boats would be built in Australia.

It’s not really a plan, since nobody involved in delivering it, least of all the US government, has signed up to it. So it’s an idea or a concept. But is it a good concept?

At one level, we would say it is, because it’s virtually the same as one we discussed last year in our detailed study of the issues that the government needs to address in order to establish an SSN capability. We considered four build strategies. The third we termed ‘kickstarted continuous build’. Under that approach, the first SSN would be built wholly overseas, the second would be partially built overseas but integrated in Australia, and eight boats would be built here.

We noted that Australia could aim for 2030 for the first boat, with the second in the mid- to late 2030s. There were two key challenges. The first was that the US Navy would have to provide us with one of its own boats. The second was that it ‘would require … rapid development of the enabling systems to support the operation of the boat once it’s delivered’ and ‘an early ramp-up of the uniformed workforce’.

Let’s look at how that gels with the USN’s own plans. Congress requires the navy to publish its shipbuilding plan every year. Over the past several administrations, the goal has been to increase the number of SSNs. That’s because submarines are one of few assets the USN has that can avoid the Chinese military’s anti-access capabilities such as anti-ship ballistic missiles. The precise target number has varied, but it’s consistently been around 60 to 72 by the middle of the century.

In the shorter term, however, the USN is experiencing a submarine capability crunch. First, this decade the number of boats falls below 50, to as few as 46 in 2028, and it doesn’t get back to 50 until 2032. That’s because the older Los Angeles–class SSNs are retiring as their nuclear fuel runs out. The Los Angeles boats were delivered at around three per year and consequently are retiring at a similar rate. But for over a decade the USN was acquiring only one new Virginia-class boat per year. Now, after significant investment to improve the US’s industrial base, they are being delivered at two per year. But the USN is still playing catch-up.

Second, the capability shortfall is exacerbated by the planned retirement in the next few years of the USN’s four SSGNs, former ballistic missile submarines that have been converted to carry 154 Tomahawk missiles each. To compensate for the missile launch cells that are going out of service, the latest batch of Virginias, the Block V variant, have a hull-lengthening ‘plug’ inserted that will increase their number of Tomahawks from 12 to 40. But since they also need to account for the 12 Tomahawks on each of the retiring Los Angeles boats, they won’t completely compensate for the SSGNs.

There’s been discussion in the US about expanding its industrial base to produce more SSNs. That’s not straightforward. The USN has stated it would take investments of US$1.5–2 billion to do that and require an increased workforce. The USN’s shipbuilding plan is already facing affordability pressures. Moreover, the USN has also started construction on a new class of ballistic missile submarines (SSBNs), which are its highest priority, and the competition for resources is causing delays to the Virginias.

There have been suggestions that Australia could help pay to set up a third production line. But even if we made those investments today, they wouldn’t produce any additional boats this decade. It’s currently taking US yards seven or eight years to build an SSN (even before we factor in the delays in production of Block V boats). The last boats scheduled for delivery in the 2020s—the boats in the Hellyer–Nicholls/Dutton concept—have in fact already started construction. So even if we helped invest in developing more construction capacity in the US, it would likely be close to the mid-2030s by the time they could deliver any additional boats beyond those currently planned by the USN.

In short, for Australia to get any US SSNs this decade, the USN would have to give up some of the boats baked into its own plans at a time when it needs every single one it can get to stop any further decline in boat or missile numbers.

That’s before we get to the second challenge: the rapid ramp-up of the enabling systems. As we and others have written, there are many other elements to an SSN capability than the boats. Vice Admiral Jonathan Mead, the head of the nuclear submarine task force, has emphasised that Australia will need to demonstrate that it can exercise ‘responsible stewardship’ of the nuclear technologies. This will require a larger uniformed workforce, which will require substantially different qualifications. A Collins-class submarine has one engineer-qualified officer; all 15 officers on a Virginia are nuclear-qualified. It will also require the maintenance infrastructure as well as the safety and regulatory ecosystems. That takes time.

Does that mean we have no hope of accelerating an SSN capability?

Building SSN’s Overseas

For the US providing Australia with Virginia-class submarines this decade would require the US Navy to give up two of its nuclear-powered attack submarines (SSNs) at a time it is facing a capability crunch of its own. While anything is possible, it seems unlikely, particularly when we also consider that Australia will also need to demonstrate that it can exercise responsible stewardship of the nuclear capability.

What, then, can Australia do to accelerate the development of a usable SSN capability? To really unpack that question, we first need to have an uncomfortable conversation about sovereignty. The term is almost omnipresent in discussions of defence capability and industry. In 2017, the previous government released 10 sovereign industrial capability priorities, which later grew to 14. It also announced a sovereign guided-weapons enterprise. But what people mean by sovereignty, what an acceptable level of sovereignty is (if there really is such a thing as partial sovereignty), and how we are to achieve it vary considerably.

The bottom line is that there are very few military capabilities in which Australia is truly sovereign. One of the original 10 sovereign industrial capability priorities was ‘Collins Class submarine maintenance and technology upgrade’ (although Defence still hasn’t released an industry and implementation plan for it). When measured by the percentage of Australian components used in the sustainment of the Collins class, a high degree of sovereignty has been achieved. But its Mark 48 heavyweight torpedo is American, and if we were denied resupply of torpedos in a conflict, that capability would degrade quickly.

There was little that was truly sovereign about the construction of the Collins even though it was done in Adelaide; we used an overseas design and most of the major components came from overseas. Similarly, the Collins life-of-type extension will install replacement diesel generators and main motors sourced overseas.

We are constantly making decisions about where we can accept dependence or reliance and where we want to spend the money, time and effort to achieve greater levels of sovereignty or self-reliance. The Royal Australian Air Force has felt no need to have a sovereign aircraft design and construction industry, instead preferring buying off the shelf and putting its effort into local sustainment. It’s an approach that has worked well.

In maritime capabilities, we’ve built ships here (on and off), but there’s no evidence to say that we need to do that in order to sustain them here. While local construction can be helpful for establishing local sustainment (although we’ve struggled to sustain some locally built vessels), the evidence would suggest that the additional cost of local construction has not led to commensurate sustainment savings.

When we look at SSNs, it’s important to accept up front that this is a capability where we will have relatively low levels of sovereignty. Certainly, we should aim for a level of sovereignty that enables an Australian captain to carry out the intent of the Australian government. We should aim for the ability to do as much sustainment as possible in Australia, including deep maintenance. It’s unacceptable to have to return a boat to the parent nation whenever maintenance is needed. But we also need to accept that we will always be dependent on supply chains back to the submarine’s parent nation.

One of the key questions the multi-agency nuclear-powered submarine taskforce will need to address is whether constructing SSNs here provides any benefits to the sovereign operation and sustainment of the capability in return for the significant increase in cost, schedule and overall risk that will inevitably arise from establishing local production. Our own sense is that any benefits are far outweighed by the costs.

Ultimately, this is a capability that can only be delivered, operated and sustained with a high level of ongoing cooperation with the parent navy and nation. Once we accept that, we can explore how conducting the SSN enterprise as a joint one between Australia, the UK and the US enhances the combined military capability of all three countries—which is, after all, the intent of AUKUS.

Before committing to build all of the SSNs here, we need to examine industrial strategies that better meet the intent of AUKUS. Once we open the aperture of the lens with which we are scrutinising possible industrial strategies to look beyond the approach of building all boats in Australia, new options come into view that can potentially accelerate the production schedule, increase alliance capability and, importantly, generate enduring industrial benefits for Australia.

The first of these options is the concept of building the first boats on an existing production line in the parent country and then building the remaining boats in Australia. That has many benefits. From an industrial perspective, it allows the shipyard workforce to be trained by working in mature, functioning shipyards. It gets submarines delivered earlier. If we accept that the initial boas will primarily have a training function for the first five or so years, early boats can help develop a uniformed workforce on the job. It can also help develop the ‘nuclear mindset’ necessary for a mature SSN capability.

In the early years, novel approaches to command and crewing will be needed. The first boat may even need to remain a USN boat until Australia’s navy meets the high bar of nuclear stewardship. There will no doubt be challenging legal, political and cultural issues to tackle. But an extended transition period working with a small number of co-crewed SSNs will help mitigate the shock of the new. Can the Australian navy really move straight from an ageing Collins capability with a relatively small workforce to a conveyor belt of SSNs being delivered on a two- or three-year drumbeat? Such a rapid transition will likely break the submarine force.

When we open the aperture even further, another approach comes into view, which we termed ‘a joint submarine enterprise’. This approach starts by accepting that Australia’s SSN enterprise will never be separate from the parent nation’s. Consequently, rather than inefficiently seeking to duplicate the entire enterprise, it pursues a division of labour that benefits both nations. This approach would consciously avoid the cost, schedule and risk overhead of building boats here.

Noting that the intent of the submarine taskforce appears to be acquiring precisely the same design as that operated by the parent navy, building here only introduces design risk since there will inevitably be modifications introduced into the design (as the sorry saga of the Hunter-class frigate forcefully reminds us).

That doesn’t mean Australian industry misses out. First, we could adopt a joint strike fighter approach of supplying components, subassemblies or even modules into overseas production lines. That involves Australian industry in the construction of a fleet of more than 60 boats (if we go with the US), rather than eight. This approach also benefits the US by expanding its own effective production capabilities. It also avoids the impossibly contorted gymnastics involved in trying to establish a viable continuous build program around a fleet of only eight boats. If those Australian-made components are ones that are essential to the sustainment of the boat, even better.

And that gets us to the key point. In an environment where our human, financial and industrial resources are limited, does it make sense to dilute them by splitting them between construction and sustainment? Sovereignty rests in our ability to sustain the boats, so that should be the priority. Even that will create huge industrial demand. We have noted that a deep-maintenance activity on a Virginia-class submarine was nearly three times as much effort as a Collins full-cycle docking. Indeed, the sustainment of a fleet of eight SSNs would likely involve more work than the build of the Attack class and the sustainment of the Collins class combined. Put another way, if we are trying to both build and sustain SSNs here, we may fall short of being able to do either.

Another element of the JSF approach is that Australia has become a regional maintenance hub for the international F-35 fleet. By taking this approach with SSNs, we can provide significant value to our AUKUS partners. The USN is facing a huge maintenance backlog for its nuclear submarine force. By focusing Australia’s industrial efforts on sustainment, we not only avoid adding to that problem, but can potentially help to reduce it. Again, there are significant, unprecedented issues here around the USN’s willingness to have maintenance done at an overseas yard, but if it means that its boats spend less time out of service then it would be a win for all partners.

A Long Transition

But the government, when taking all elements of the wicked submarine problem into account, may choose to build the SSNs in Australia. Building here may deliver significant sustainment benefits. It may be necessary to develop the expertise needed to exercise responsible nuclear stewardship. Our strategic partner in the US or the UK may not have the capacity to build submarines for us. These are all issues that the nuclear-powered submarine taskforce will need to assess in preparing its advice to the government.

Whichever industrial path the government chooses, we are looking at a very long transition from the Collins class to the future SSN fleet. There are many key milestones on that path, and while most attention is directed towards when the first boat will arrive, that’s not necessarily the most important one; a single boat does not a capability make.

All capability transitions are difficult and the submarine one will be the most challenging that the Department of Defence (and the nation) has ever undertaken. It’s impossible to prepare for that transition without knowing how long the journey will last—and it will extend well past delivery of the first boat.

Our starting point is that an SSN has a useful life of 30–35 years. The Royal Navy’s most recent Trafalgar-class retirees were over 30. The most recent US Navy Los Angeles–class SSNs to be retired have averaged around 35 years of service. Some, like USS Bremertonand USS Jacksonville, served for 40 years. It’s true that in the 1990s and 2000s, some were retired at a much younger age as the US, like all Western countries, sought to harvest the post–Cold War peace dividend. But that’s not the world we are facing now. Western navies desperately need submarines and, considering the huge investment required, they want to maximise the return.

What does that mean for the schedule of a potential Australian build program? Let’s start with a continuous build program, that is, one that rolls straight into the replacement project once the first one is finished so that there are no ‘valleys of death’ in which production stops, workers are laid off and key skills are lost. Eliminating the ‘stop-start’ nature of Australian naval shipbuilding was one of the main goals of the previous government’s continuous naval shipbuilding program.

But such a program has disadvantages. One of the reasons that support for the 12-boat Attack-class program evaporated was the growing realisation that its two-year delivery drumbeat to support a continuous build program meant the new capability would be delivered too slowly, either to meet Australia’s worsening strategic circumstances or to mitigate the risk of a capability gap as the Collins aged out.

But the SSN drumbeat will likely be even slower than the Attack class was set to be. The previous government announced it would acquire ‘at least’ eight SSNs. If we assume a service life of 30–35 years for our SSNs, a continuous build program for a fleet of eight boats would require a four-year delivery drumbeat to stretch the program out so that the there’s no gap between the last boat of the initial build program and the first boat of the successor program. For a fleet of 10 boats, it would be between three and three-and-a-half years.

That’s borne out by the experience of the UK. The RN has a combined fleet of 11 nuclear boats between its SSNs and ballistic-missile submarines (SSBNs), which means it implements a delivery drumbeat to support a continuous build enterprise that alternates between SSN and SSBN programs (the Astute-class SSN program is nearing completion as the Dreadnought-class SSBN program ramps up).

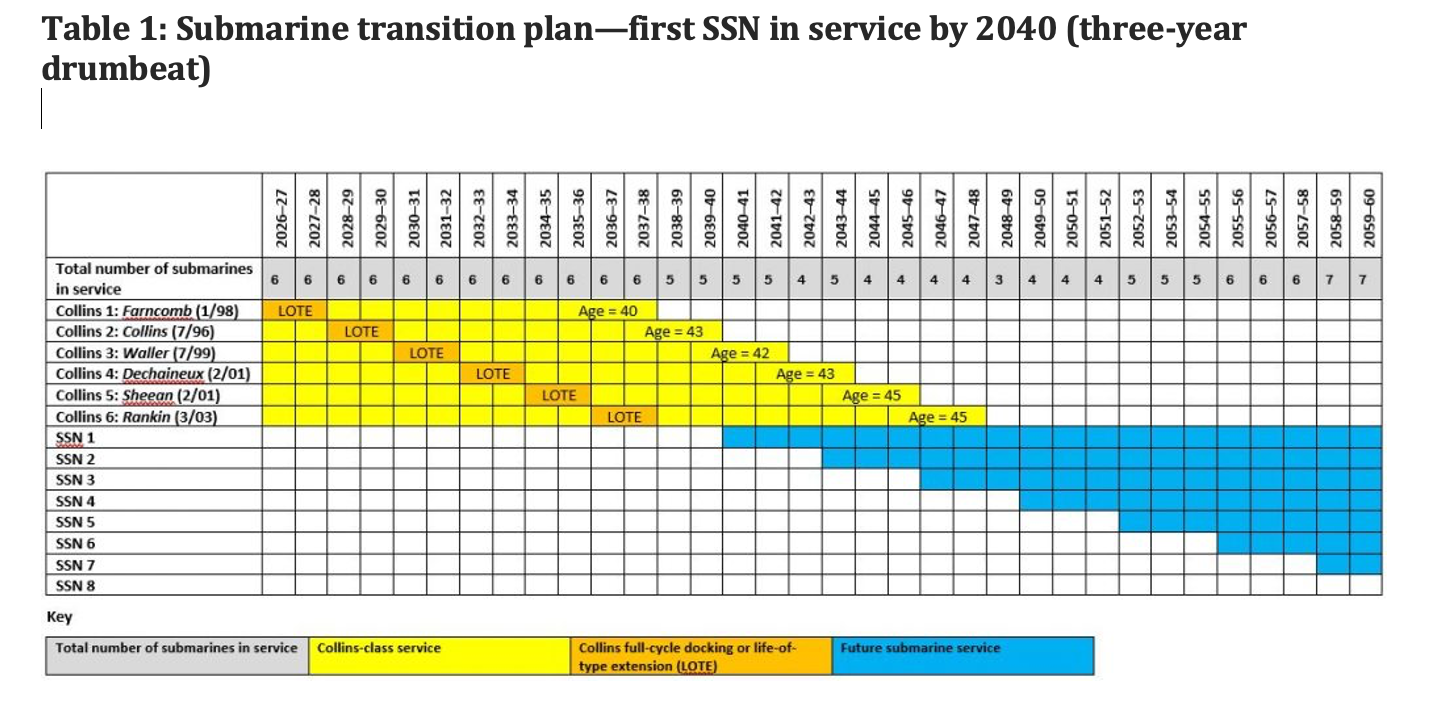

But that delivery drumbeat has implications for capability (and the lack of it). If we assume the first boat is delivered in the late 2030s and enters service in 2040, that means boat two is between three and four years later—around 2043–44—and the third boat somewhere around 2046–48. If we assume the rule of threes (three vessels, squadrons, brigades, etc. are needed to reliably deploy one), then Australia won’t have an SSN capability until the second half of the 2040s, which is a quarter of a century away. That’s also the point at which the last of the Collins will reach its retirement date after having completed its life-of-type extension in 2038. We’d need to be confident that three SSNs would be a sufficient capability to move to the post-Collins world.

Table 1: Submarine transition plan—first SSN in service by 2040 (three-year drumbeat)

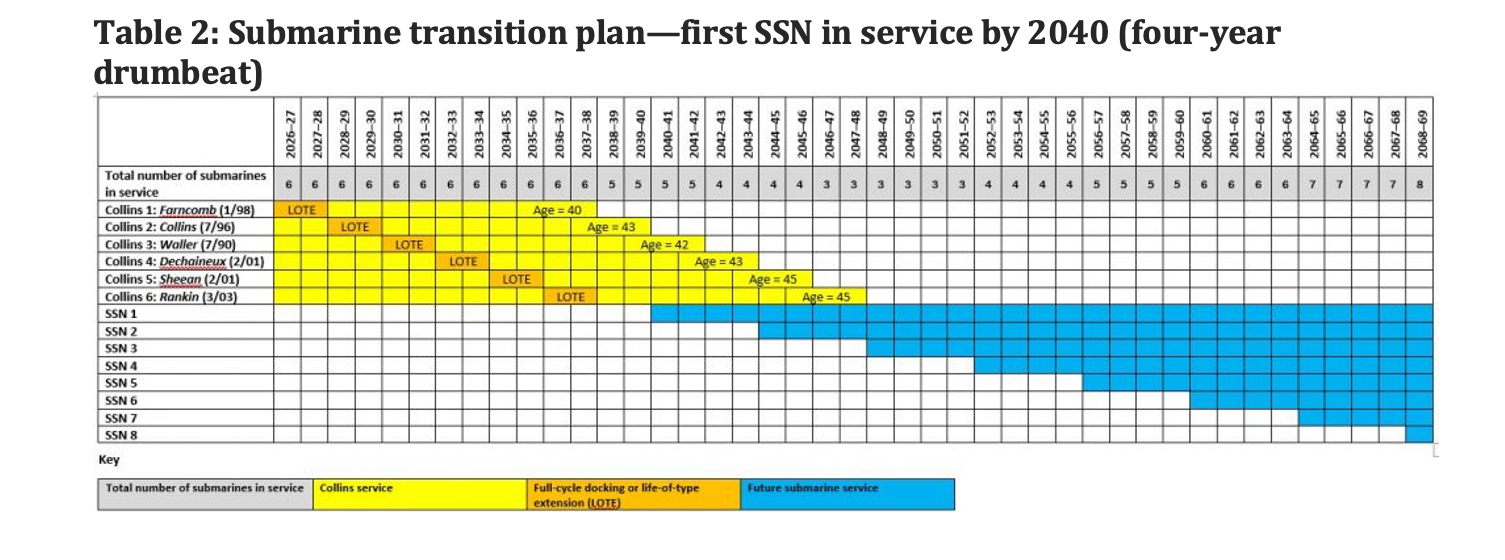

The worst case, building on a four-year drumbeat to replace the first SSN when it is around 30 years old, means we wouldn’t have the full capability until close to 2070. That’s a really long way away.

Table 2: Submarine transition plan—first SSN in service by 2040 (four-year drumbeat)

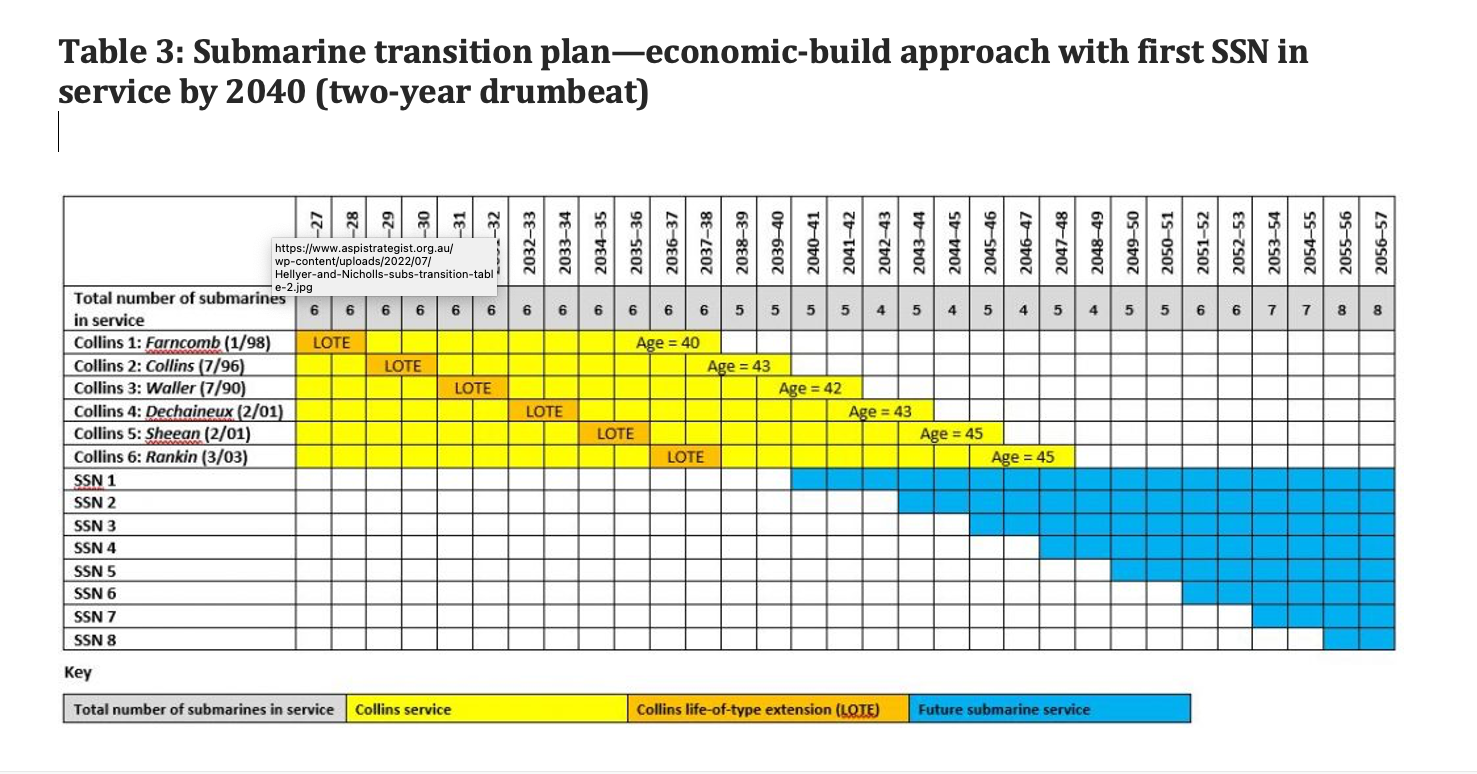

To achieve the full capability sooner, we could aim to build the SSNs faster than a three- or four-year drumbeat. On a two-year drumbeat we’d get the eighth boat in the mid- to late 2050s. Then there’s the question of whether that can actually be achieved. A Block V Virginia-class SSN is over 10,000 tonnes. The next generation of US Navy SSNs will be even bigger. That’s a lot of boat to build.

But even if we can achieve it, building faster also breaks the continuous build program. If we are building an eight-boat fleet on a two-year drumbeat, the last one arrives 14 years after the first, well before it’s time to replace it. You could retire and replace the first boat when it’s 16 years old, but only halfway through its economic life. Or you could keep the early boats in service and add to them, creating a bigger fleet. But that comes at a massive financial cost. If the RN can only afford seven SSNs, can we afford the 15 or more needed to support a two-year production drumbeat?

Table 3: Submarine transition plan—economic-build approach with first SSN in service by 2040 (two-year drumbeat)

The other option is to stop building at eight or 10. But then we’d be back into the stop-start approach to shipbuilding that the previous government’s continuous naval shipbuilding program sought to address. We would be building in a valley of death from the outset.

How do we break out of this conundrum? One possibility is to not go down the path of building boats here in the first place and instead adopt the enterprise approach discussed in our previous post, which of course assumes our major partner has the capacity to build our boats for us. But even that approach will likely get us well into the 2050s by the time we have a full SSN capability.

Whichever way we look at it, we are facing a long transition, one that could potentially last into the 2060s. That fact has to be a central tenet of our planning. Once we accept that, we can chart a course that addresses any capability risks presented by the extended timeframe. The most obvious of those risks is the Collins class ageing out before the SSN capability is serviceable.

Defence Minister Richard Marles has said his mind is open on how to bridge a capability gap. There are a range of options. In our next post, we’ll start our consideration of the one that has attracted the most attention to date—a new conventional submarine.

The Conventional Submarine Gap Filler

The government has announced a defence strategic review to ensure Australia ‘has the right capabilities that are postured to meet the growing strategic challenges that Australia and its partner countries will face in the world in coming years’. Earlier in this series, we looked at Australia’s transition in undersea warfare capability and highlighted the risks involved in that long process. One of the review’s highest priorities will be to address those risks.

While there are several broad paths to mitigating them, the acquisition of a new conventional submarine has garnered the most public attention. It seems likely that the review will consider the merits of the concept. Its analysis will be informed by the nuclear-powered submarine taskforce’s assessment of the optimal pathway to acquire these nuclear-powered attack submarines (SSNs).

We look here at whether a new conventional submarine could address the transition risk. It would need to address three broad challenges to win the review’s support:

- capability deficiencies, namely that the Collins-class submarine ceases to meet Australia’s undersea warfare requirements

- platform availability, namely that the Royal Australian Navy no longer has sufficient submarines to meet its requirements

- workforce availability, namely that the navy doesn’t have sufficient submarines to generate the uniformed workforce needed to transition to SSNs.

Of course, these are intertwined; there’s no point having lots of submarines if they’re not survivable, for example. There are quality and quantity risks, and we should be mindful of the transition from the Oberon class to the Collins. By the time the first Collins was commissioned in 1996, Australia’s submarine fleet had fallen from six to two and the navy was struggling to maintain its workforce. It took years to recover.

It’s hard to discuss quality issues, particularly since Defence itself doesn’t seem to have a clear view on what comprises a viable capability. For years, senior officials told the Senate the Attack class would remain a ‘regionally superior capability’. Yet, shortly after its cancellation, former prime minister Scott Morrison said it was the unanimous view of Defence’s senior leadership that the Attack class would have been obsolete the moment it was launched.

If our capability requirements can only be met by an SSN, then no conventional submarine can ever meet them. Nor can the Collins, even after going through a robust life-of-type extension (LOTE). But since many advanced nations are still designing, building and operating conventional submarines, it would appear there’s some life left in the concept.

One might argue that the LOTE program will ensure the Collins will continue to deliver adequate capability throughout its very long life with new diesel generators, main motors, electrical distribution systems and optronic sensors in place of periscopes.

But it’s unlikely that the LOTE will substantially improve available power, the submarine’s capacity to sustain longer patrols, faster transits or noise generated from the current hull shape. In addition, many more modern submarines have adopted impellor arrangements to reduce the noise and cavitation issues associated with their propellers. Defence has also rejected incorporating air-independent propulsion (AIP) that would allow the submarine to remain submerged for longer. It is highly doubtful that the Collins upgrades will keep pace with China’s growing submarine and anti-submarine capabilities, and those of other potential adversaries.

However, more modern submarine designs than the Collins are now available. Ten years ago, on Defence’s recommendation, the government rejected an off-the-shelf design for the Collins’ replacement, but submarine design has progressed significantly since then, and dramatically since the Collins design was completed in the 1990s. Certainly, smaller European designs don’t have the range of the Collins, let alone of the Attack class, but they do have enhancements such as AIP. And large conventional designs, such as those of the Japanese and Koreans, are in a similar class to the Collins while possessing advantages such as AIP and lithium–ion batteries.

But it’s highly likely Defence will have to moderate its requirements and accept the art of the possible. Arguably, the Attack class collapsed under the weight of its own contradictions because we sought to design a conventional boat with many SSN capabilities. If Defence follows the same path now, it will meet the same result.

One approach could be a high–low capability mix, with Collins then the SSN providing the high end and an off-the-shelf design providing the low end. Considering Chinese warships are now frequent visitors to our near region, a small but stealthy submarine could provide useful capability close to home.

Turning to quantity, or platform availability, it’s important to remember that with a minimum of three boats needed to reliably deploy one, the best we can hope for from the six-boat Collins fleet is two deployable boats—and that’s world’s best practice. That’s despite the government stating in the 2009 defence white paper that we need more submarine capability and every subsequent government reinforcing that assessment.

The LOTE can’t improve on that, and there’s a distinct possibility of availability declining. Each LOTE installation is intended to fit inside the two-year full-cycle-docking window currently built into the Collins’ maintenance cycle. But if technical risks associated with a very ambitious program of modification push that schedule out, the boats will spend more time out of the water and less time in training or on operations. And there’s no way the LOTE can replace every ageing component on boats that will need to serve into their forties. Unplanned defects will increasingly see boats out of service for maintenance. Australia’s submarine force could experience a re-run of the Oberon–Collins transition, with capability falling to catastrophic lows.

Delivering new conventional submarines could increase quantity—but only if Australia exercises discipline. Much of the benefit will be undone if we must wait until the mid- to late 2030s for any new boats. That means sticking as close as possible to an existing design and making hard prioritisation decisions, such as choosing a rapid schedule over integrating the US combat system.

It also means some very hard thinking about where to build them. There will no doubt be political pressure to construct them in Australia. There will also be concerns raised about our ability to build both the conventional boat and the SSN here. But we can’t procrastinate and repeatedly change course for 13 years and expect to have the same freedom of choice as when we started down the submarine replacement path in 2009. Just as we need to consider all industrial strategies when it comes to SSNs, we need to consider all approaches to the new conventional boat. We could prioritise building the SSNs here and acquire the new conventional boat overseas—or the other way around. But the days when the mere thought of building any vessels overseas was anathema are long gone.

The quantity of boats is closely related to the third risk: the number of submariners. It’s no coincidence that Defence and its industry partners’ efforts in achieving world’s best practice in submarine availability have allowed the navy to finally generate the number of submariners it needs to operate the Collins fleet. That’s around 750 (a crew of 56 times 6 boats times a redundancy factor of 2–2.5). But by the time the SSNs are all in service, that force will need to be more than 2,000, perhaps even 2,500. It goes without saying that the navy can’t get from 750 to 2,500 overnight. But even finding the personnel for the first SSN—potentially 140 for a single US boat—from a pool of 750 will be challenging when the bulk of that pool is still needed for the Collins.

In short, the navy needs a way to grow a workforce at an achievable rate at a time when Collins availability will likely be declining. We have examined a range of options to increase submariner numbers. While this analysis is not exhaustive, it indicates that an additional four conventional submarines supplementing the six Collins would provide the most achievable growth path to a fleet of eight nuclear boats. That scenario would require an ambitious but manageable average annual workforce growth of around 4%, smoothing out a growth rate that could be twice as high if the navy went straight from the Collins to SSNs.

Of course, no number of conventional submarines will address the other part of the workforce requirement, namely the ability to safely operate a nuclear submarine. That will require nuclear specialists within and outside Defence. The navy will need to learn how to operate submarines very differently, both tactically and strategically.

While some nascent workforce capability could be developed through participation in US and/or UK nuclear submarine programs and joint crewing, it will be difficult to establish and sustain a critical mass of nuclear-qualified workers until SSNs are available to Australia. It may be that the SSN delivery schedule is driven more by Australia’s capacity to expand its nuclear workforce than by construction capacity.

In sum, another conventional boat could mitigate some of the key risks we face in our long submarine transition. But the review team needs to remind Defence that the perfect (whether it be military capability or local industry involvement) is the enemy of the good and its quest for submarine perfection has so far delivered nothing. Australia’s ambitions in both areas must be moderated if it is to get a new conventional submarine in time to help address those risks.

The other unavoidable issue that must be factored into the review’s considerations is, of course, funding. An additional conventional submarine will come at great cost. We have previously outlined the pressures on the defence budget that SSNs will only exacerbate.

With substantial new funding looking unlikely with the broader pressures on the public purse, finding the money for a new conventional submarine would involve cancelling other capabilities in Defence’s investment program. That will likely require strong recommendations from the review, and resolute backing from the government.

Editor’s Note: We put together the four part series into a single piece.

The four parts were publised by ASPI as found below:

https://www.aspistrategist.org.au/can-australia-get-nuclear-powered-submarines-this-decade/

Marcus Hellyer is ASPI’s senior analyst for defence economics and capability; he is on Twitter at @Marcus_ASPI. Andrew Nicholls is a former director in KPMG Australia’s Finance Strategy and Performance Division and has held senior positions in the Department of Defence and been an adviser and senior adviser to three defence ministers on budgetary and capability matters.

The featured photo is of a Collins class submarine and is credited to the Australian Department of Defence.