F-35 Production Process

This weekly video is built around a recent Defense News video as well as a paper published earlier this year by the Lockheed Martin leader highlighted in the video, Donald Kinard.

In this Defense News video, an interview with Don Kinard, Senior Fellow for F-35 Production, provides an overview on the production process used to deliver the F-35.

We have published interviews with the Lockheed Martin manufacturing guru over the years and will be publishing soon his latest update on the program from the manufacturing perspective,

In a recent paper which he delivered at a 2018 Aviation Technology, Integration and Operations Conference which focused on the history and evolution of the F-35 as a production aircraft, Kinard provided an overview on digital thread and advanced manufacturing used in the F-35 manufacturing process.

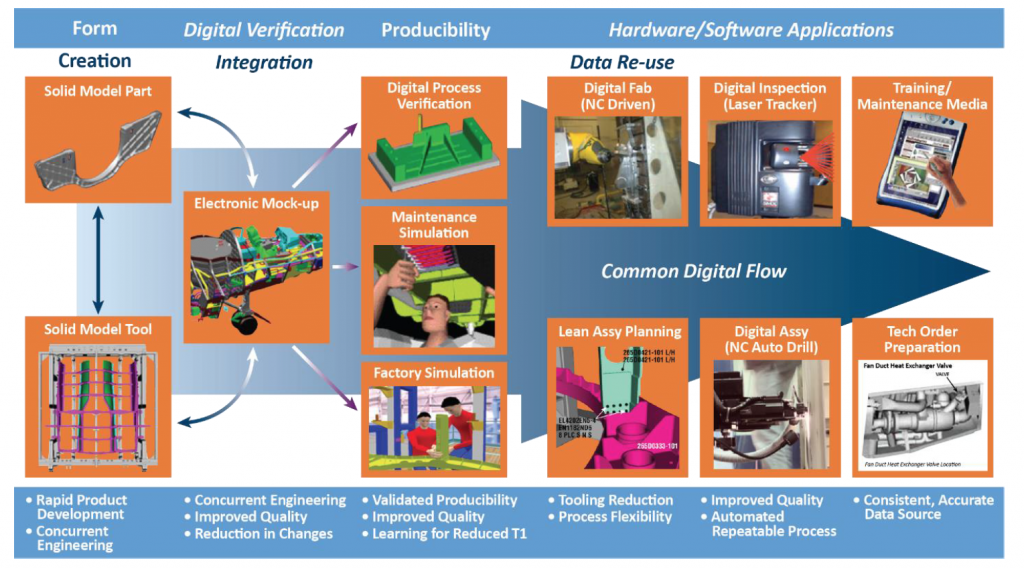

The graphic below from that paper provides an overview on his discussion of F-35 digital thread manufacturing.

A section of that paper follows:

The F-35’s development and early production benefitted significantly from the phased adoption of a digital thread philosophy. Designers produced 3-D solid models, constructed them to support factory automation, and facilitated their consumption by downstream manufacturing and sustainment functions.

Recently, technology has allowed the rapid validation of as-designed to as-built configuration verification through the use of laser scanning and structured light technologies.

The term digital thread was reportedly coined by the Air Force Research Laboratory (AFRL) and Lockheed Martin during the early days of F-35 development.

The overall F-35 digital thread philosophy is depicted in the figure above.

Lockheed Martin defines it as the creation, use, and reuse of the 3-D models by engineering and downstream functions, including manufacturing and sustainment.

Phase 1

In Phase 1 of the digital thread implementation, engineering produced exact 3-D engineering models and 2-D drawings. Partner and supplier models, 3-D tool designs, drawings, specifications, and related analysis data, were released into a common product life-cycle management system for accessibility and configuration integration. Manufacturing produced 3-D models for tools and factory layouts that improved facilities development and installation.

For many of the airframe parts, engineering was able to produce reduced-dimension drawings that decreased engineering costs and facilitated supplier NC machining. Fiber placement was used for composites based on the digital thread. Coordinate-measurement machines’ inspection points were programmed directly into the solid models since the solids contained the master engineering data.

These models also supported the supportable low observable structures processes discussed earlier involving the machining of the IML/OML and cured laminate compensation.

3-D models were used for virtual mockups, manufacturing, and sustainment simulations. Significant successes of the 3-D solids led to large reductions in the quantities of engineering and tooling changes. Solid models reduced engineering changes, compared to historical numbers, because of the ability to provide accurate surfaces and improved integration between parts.

Because of solid model engineering and solid model tooling, Lockheed Martin was able to reduce tool design changes due to tool interferences with released parts. Interferences between parts were also reduced, compared to non-solid model programs, and suppliers were able to produce and validate machined parts to the released solid model masters. These improvements were especially important to the F-35 because there were three variants to design.

Assembly interface control drawings, typical of legacy programs, were not required because the solid models facilitated coordination among partners and suppliers.

Virtual manufacturing simulations, encouraged by the digital thread technology, turned out to be time consuming and expensive, so only a few areas were even attempted. This is one area requiring tool development for future programs. Physical mockups were used for specific bays depending on complexity. Sustainment engineering was able to use virtual reality helmets to assist in simulating maintenance actions with the completed 3-D engineering models.

The digital thread allowed significant increases in producibility and variation management analysis during the F-35 SDD program.

Geometric dimensioning and tolerancing was introduced on the F-35, and variation management analysis was performed by manufacturing engineering. This included using specialized 3-D software to perform complex assembly variation studies. Critical installations were identified, followed by the collection of process capabilities facilitating the variation studies and the creation of variation management documents containing assembly datum schemes.

Variation analysis led ultimately to the definition of engineering tolerances that were flowed into the models, drawings, and tooling, and to the identification of key characteristics (KCs).

A KC is a feature of a material, process, or part (including assemblies) whose variation within the specified tolerance significantly influences product fit, performance, service life, or manufacturability. The F-35 identified many KCs early on, but would likely revise selections for future programs.

KC selections should be made with the understanding that their selection will drive costs into the production system. They will have this effect by requiring the development and imposition of KC management plans, the formal collection of data by fabricators and assemblers, and reporting and analysis of deliverables. KCs should only be selected under certain conditions. Plans must first be in place to alter the engineering or manufacturing BTP designs.

Similarly, requirements must first be identified and implemented to better control or take advantage of the variation reduction. KCs that simply accentuate but do not drive changes to engineering accept/reject criteria or BTPs are not KCs.

For example, KCs were put on the diameters of holes on previous programs, but there was never a plan to change the tolerances. As such, these should not have been regarded as KCs.

Phase 2

Phase 2 of the digital thread transformation is about constructing the engineering data to support factory automation. Examples are automated drilling and robotic coatings applications. Automated drilling is used by all the F-35 partners, and we drill 20 percent of the total holes using automation. This includes 80 percent of the accessible OML holes. Automated drilling is about four times faster than manual drilling and its quality is nearly perfect, with remarkable repeatability.

Lockheed Martin uses automated drilling for the wing boxes, forward fuselage skins, and upper skin to center wing skins. We also use it for the center wing at Marietta, Georgia. Northrop Grumman uses a metrology-assisted robot to drill the narrow inlets on the F-35. BAE Systems drills its empennage skins and structure separately using its high-precision machining centers. This is a remarkable feat of high-precision machining, considering the bolt-to-hole tolerances it requires. There is a plan in place to implement even more automated drilling in the future as part of the continual effort to drive costs down and improve quality.

Other automation used for the F-35 include fiber placement technology, which Lockheed Martin, Northrop Grumman, and other suppliers use to lay up complex inlets, nacelles, and large wing parts. Recently BAE Systems also introduced a robot to countersink its composite skins.

Phase 3

Phase 3 provides the digital thread directly to the mechanics to create such products as work instruction graphics. These graphics were facilitated by the 3-D solid models, which can be used to create graphics through visualization software tools. Ideally, they would visually instruct mechanics on the floor or maintainers in the field and reduce the time it takes them to understand their tasks. However, for production this intended benefit on the floor ended up being very difficult to maintain. This was because graphics are static images that are incapable of affordably being updated as engineering or manufacturing changes. For the F-35 program specifically, with concurrent engineering and manufacturing development, graphics must frequently be updated to accommodate a steep initial learning curve and significant engineering, tooling, and planning changes.

An unexpected factor in this process was the impact of flow-to to-takt manufacturing on graphics creation. As the takt time (production rate) changed, new tool positions were added and hours per unit decreased. As a result, the manufacturing sequencing needed to be adjusted constantly by breaking up planning cards and redoing graphics. In an effort to circumvent static graphics costs, graphics can be made available on the factory floor. This is done by granting the mechanics access to the visualization tools from their work terminals. Harness installations are a good example of how this can work because harness routings are especially difficult to understand from a 2-D drawing. Early in SDD, large television monitors were placed in some of the work areas, and the mechanics used these until experience was gained with the installations.

Another downside of graphics is that the mechanics typically only need them for a short time. Despite this, however, graphics do help mechanics who are new to the F-35 program during ramp-up to full-rate production. Recently, movies of the critical installations were produced that could be accessed as needed through the electronic work instruction terminals that mechanics use on the floor.

One of the unique ways for mechanics to use the digital thread is through optical projection technology.

Mechanics can use this to visually project work instructions directly onto the aircraft. For example, fastener locations and part numbers are projected onto the inlets being built at Lockheed Martin’s Marietta facility. The conventional procedure requires mechanics to look at drawings and write down part numbers and inlet locations to do their work. With the digital thread’s procedure, mechanics can instead view the projected instructions while performing their work.

Continuing work is being done to capture the actual fastener grip during automated drilling operations. This information will be used to eliminate grip validation time and support fastener projection. In addition, it will be used to kit, clean, and promote fasteners and deliver these to the point of use.

An additional example of Phase 3 is the technology for laser ply projection in the composites shop. This was one of the first Phase 3 digital thread technologies used in the aerospace industry. Bulkhead marking was initiated on the F-35 where ink jet markings for bracket locations were printed directly onto large bulkheads. This saved span and costs and eliminated thousands of tools that had to be designed and maintained.

The production of tools for the mechanics and sustainment modifications using additive manufacturing is another digital thread success.

Lockheed Martin has produced more than 5,000 tools for the floor and field using fused deposition modeling (FDM) of polymers. FDM provides a fast, low-cost approach to producing temporary tools (temporary because of the FDM material’s durability issues) to assist the mechanics. The development of more durable FDM materials continues in the industry. The objective is to enable producing permanent tooling and replacing more expensive metal, fiberglass, and other typical hole-drilling tooling.

Phase 4

Phase 4 of the digital thread is the validation of engineering as-designed to the as-built structure using advanced noncontact metrology techniques, including laser scanning and structured light. This technology can identify deviations from engineering early in the build or fabrication process and rapidly correct them, reducing cost by stopping defects from traveling downstream.

A truly revolutionary technology, it may eventually replace coordinate measuring machine inspections and become a requirement for suppliers prior to shipping parts, tools, and equipment.

Additively manufactured tools configured to mimic various F-35 weapons normally take about a full shift to be installed and pass clearance checks. Now, a laser can scan the bays and compare the as-built aircraft to the engineering models, which only takes a few hours.

As another example, when there is a fit problem with a tube on the floor, the cause is not readily apparent. The tube could be bad, the bracket location could be incorrect, or there might be a problem with the structure. To overcome the problem, the tube can be brought to a scanner and rapidly validated, or equipment can be brought to the aircraft to have the brackets and structure checked.

Current scanning technologies typically depend on targets being placed on the aircraft or parts.

However, this will eventually be replaced by feature-based recognition as the digital thread connections to the 3-D scanner technology matures. This scanning technology can also replace the thousands of the manual mismatch, gap, and flushness measurements required today.

Further, it can inspect detail parts, tooling, and assemblies on a first-article basis today. Identifying defects during first-article inspections will significantly reduce the cost and flatten the learning curve for concurrently developed products like military aircraft. Early identification will also reduce the recurring cost for measurements. In the future, the use of 3-D non-contact metrology for recurring real-time validations in an assembly, as well as for supplier acceptance, may become routine.

Applying the digital thread on the F-35 program has brought significant benefits, including the:

1) development of the BTPs,

2) use of automation to reduce touch labor and improve quality,

3) integration of the digital thread on the factory floor, and

4) opportunity to validate the configuration using digital thread technologies (e.g., laser scanning and structured light).

There has been an explosion of digital technologies in the past five years and a tremendous amount of continued development in the industry.

A future additional phase of the digital thread is discussed in the following section. It refers to the ascension of Industry 4.0 [7], the fourth industrial revolution: the revolution of data.